One of the SAE AeroDesign competition's top-performing UAVs

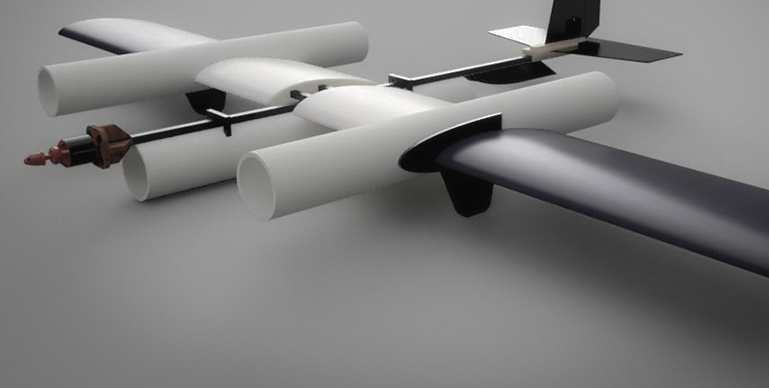

A high-performance micro-class Unmanned Aerial Vehicle (UAV) designed for the SAE AeroDesign collegiate competition in 2019. The UAV was designed for high payload carrying capacity and quick deployment. Discover the innovation behind its structure, wings, and advanced electronics.

As part of the Structures and Composites Subsystem I played a pivotal role in various aspects of this remarkable aircraft system, from component fabrication to electronic testing and data recording.

About SAE Aero Design

The SAE Aero Design competition is a real‐world design challenge designed to compress a typical aircraft development program into one calendar year, taking participants through the system engineering process of breaking down requirements. It exposes participants to the nuances of conceptual design, manufacturing, system integration/test, and sell‐off through demonstration. SAE Aero Design features three classes of competition — Regular, Advanced, and Micro. The following UAV was design to compete in the Micro Class.

The SAE Aero Design competition is a real‐world design challenge designed to compress a typical aircraft development program into one calendar year, taking participants through the system engineering process of breaking down requirements. It exposes participants to the nuances of conceptual design, manufacturing, system integration/test, and sell‐off through demonstration. SAE Aero Design features three classes of competition — Regular, Advanced, and Micro. The following UAV was design to compete in the Micro Class.

Micro-Class Design Requirements

The objective of the Micro Class is to design light-weight micro UAV style aircraft that can be quickly deployed from a small package and able to carry a large, unwieldy low density payload. For 2019, the scores were based on both the maximum performance of the aircraft and on overall performance throughout the event. The Micro Class assembly demo is mandatory timed event. Payload fraction is a core element of the class.

About AM9

The AM9 is a Micro Class Unmanned Aerial Vehicle designed by AeroMIT (an interdisciplinary student research project team) that flew in the SAE Aero Design East competition held in Texas, USA and represented the Manipal Institute of Technology in March 2019.

Within the Structures and Composites Subsystem, I had the privilege of contributing to this remarkable aircraft system. My role encompassed a diverse range of tasks, including the fabrication of aircraft components, electronic testing, flying tests, prototyping, CAD modelling, and meticulous data recording.

Aircraft Features

- 1.2 m Wingspan

- Assembled in Less Than 90 seconds

- 117 Test Flights

- 9 Iterative Designs

- 500 g Approx Empty Weight

- 1,500 g Approx Payload Capacity

- 15 Minutes Endurance

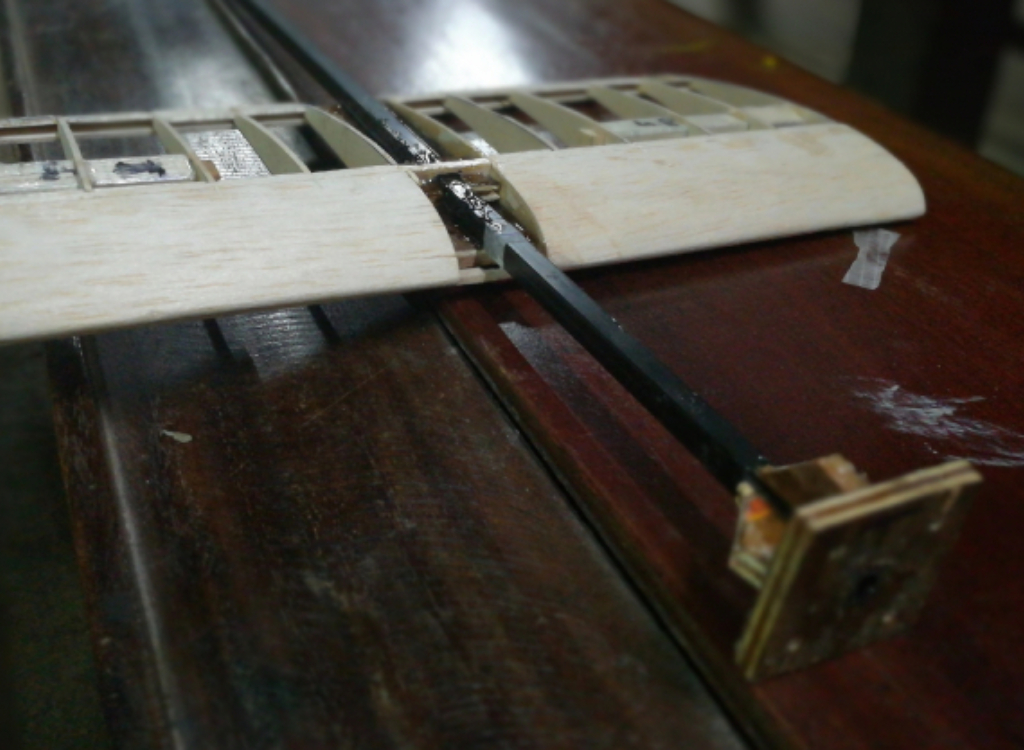

- Carbon-Fiber Composite Parts

- High Strength-to-Weight Ratio

- Compact Packing and Portable

Competition Rankings

- 5th Overall

- 6th in Design Report

- 4th in Presentation

- 5th in Aircraft Performance

Gallery

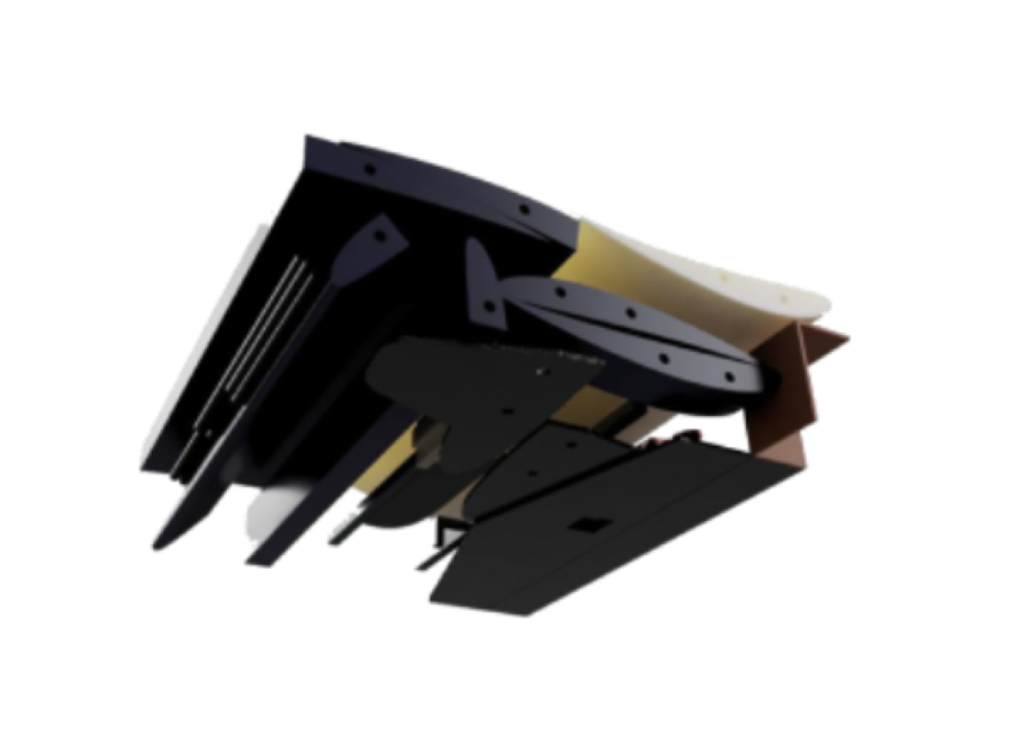

- Wing is split into 8 sections and 2 ailerons

- Fuselage and empennage made out of carbon-fibre reinforced plastic (CFRP)

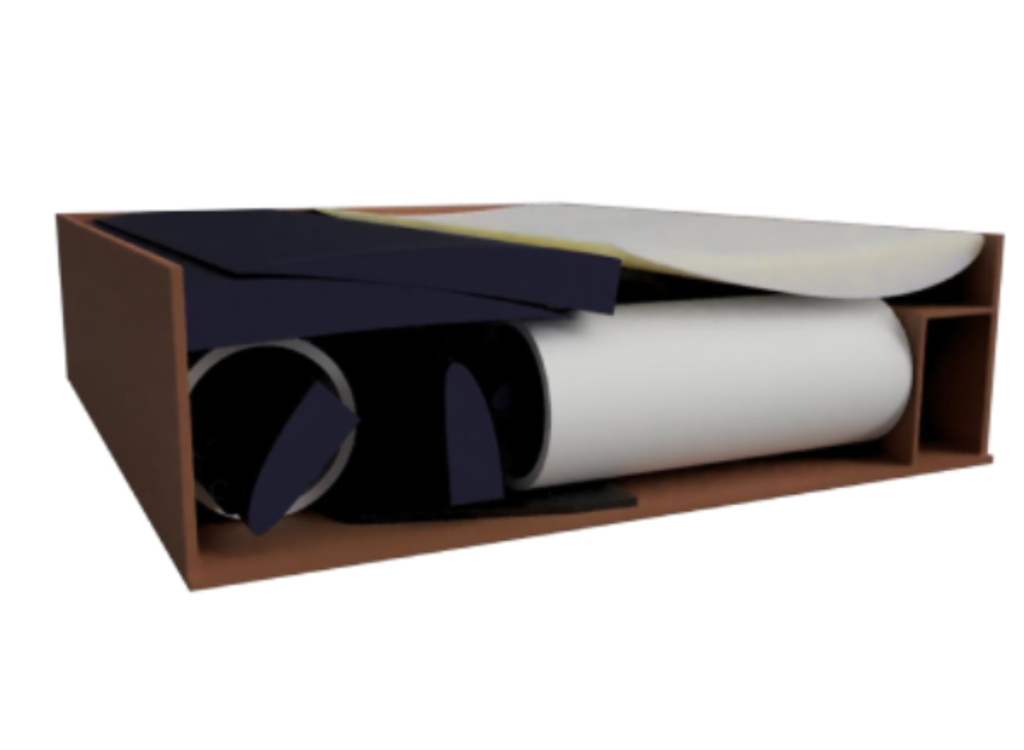

- All aircraft components including the payload (PVC pipes) placed inside a 12 × 4 × 14 inches container

- The parts can be taken out and assembled to flight-ready status in less than 90 seconds.